SUPPLY BEST BUILDING MATERIALS

Architectural aluminum panels are manufactured from high-quality aluminum alloy sheets, commonly using 3003, 5005, 5052, and other industry-recognized alloys. These alloys are widely specified in the North American construction industry due to their excellent formability, structural stability, and long-term performance.

Architectural Applications

·Building façades and curtain wall systems

·Exterior cladding and rainscreen systems

·Interior wall panels and ceiling systems

·Canopies, entrance features, fascias, and soffits

·Commercial complexes, airports, transit stations

·Hospitals, schools, office buildings, hotels

·Industrial facilities and public infrastructure

Aluminum Advantages

·Lightweight & High Strength – Reduces structural load while maintaining rigidity

·Excellent Weather Resistance – Suitable for diverse climate conditions

·Fire-Resistant – Non-combustible metal material compliant with building fire codes

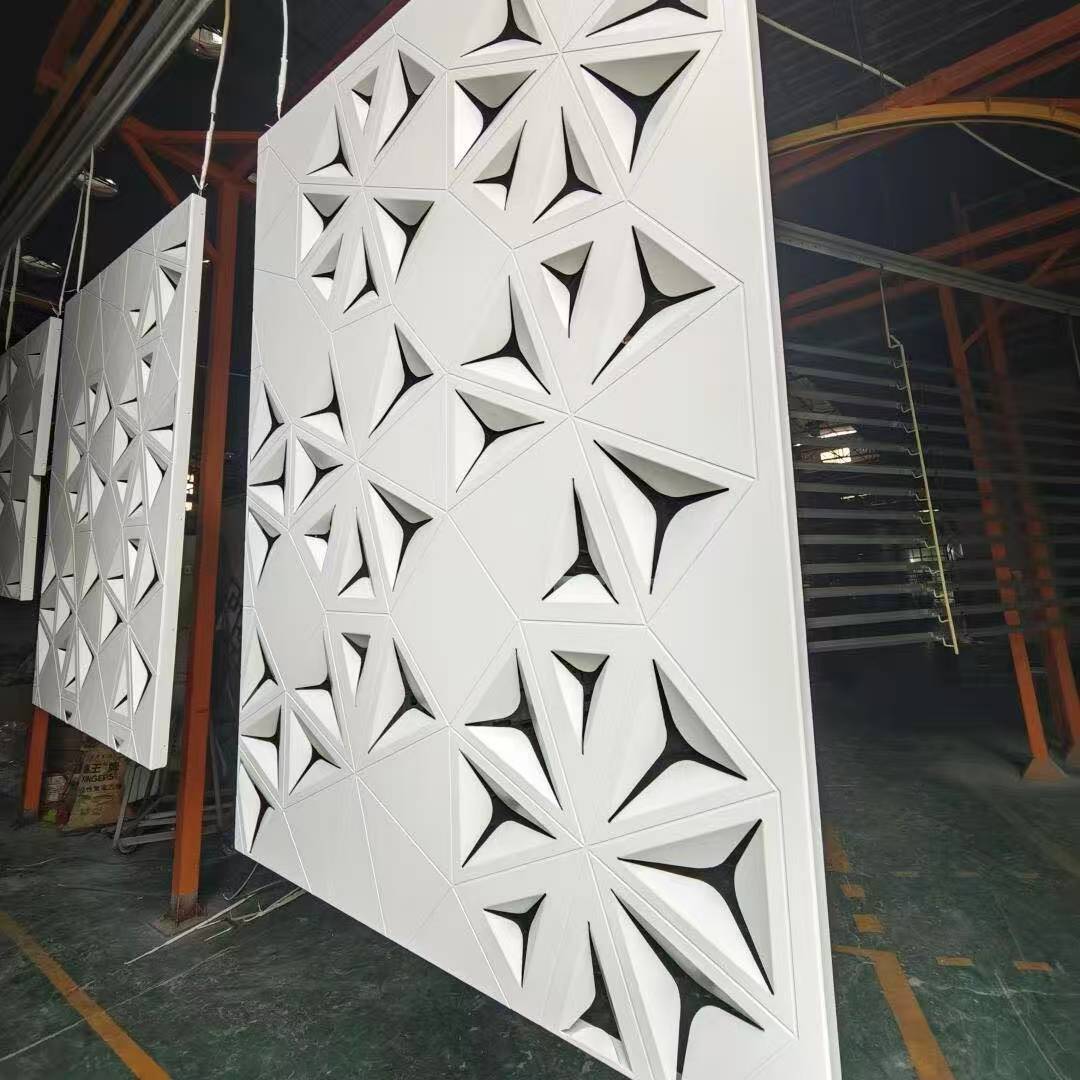

·Design Flexibility – Supports curved, perforated, folded, and custom forms

·Low Maintenance – Smooth surface with good self-cleaning properties

·Long Service Life – Stable performance and appearance over time

·Environmentally Sustainable – 100% recyclable aluminum material

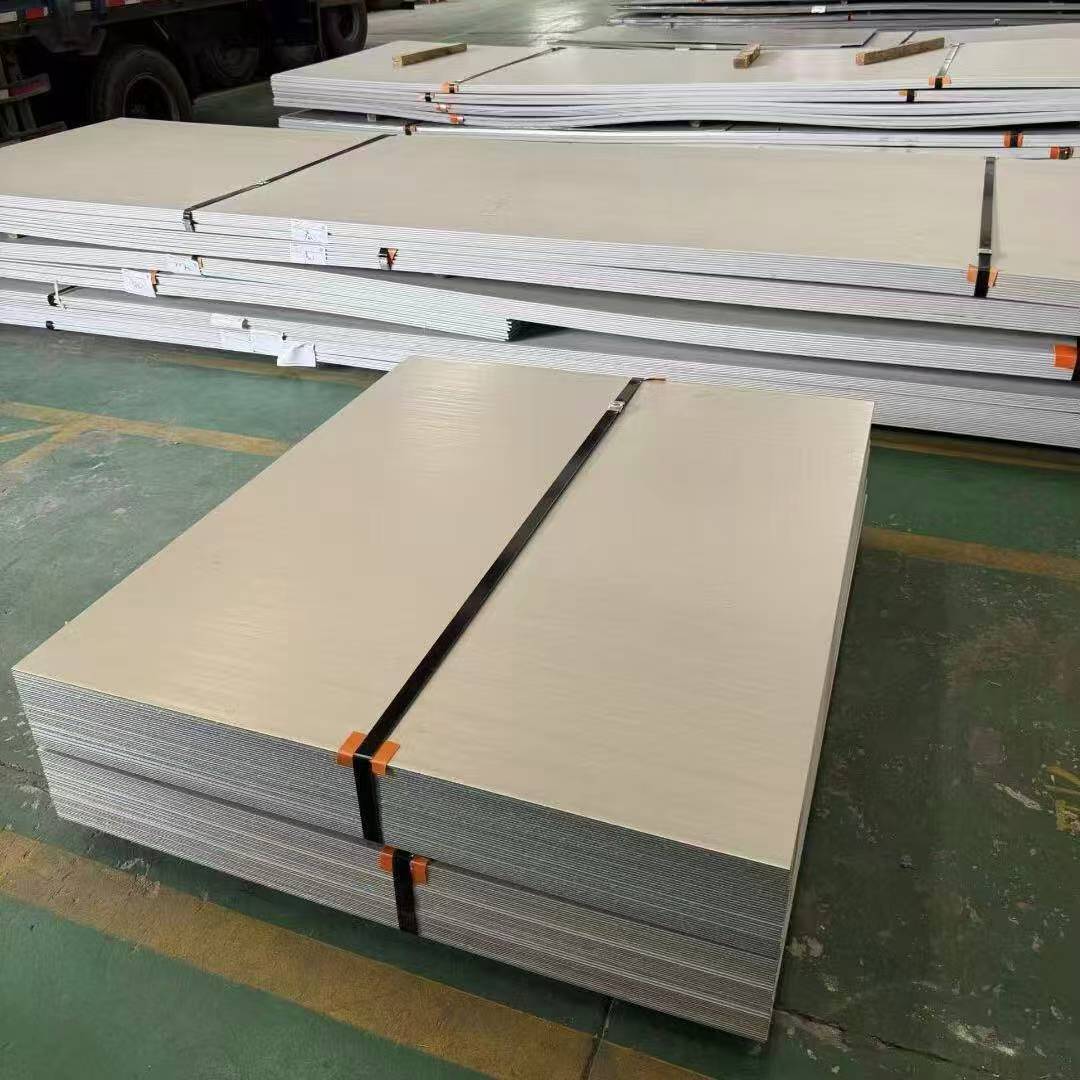

All raw materials are sourced from tier-one aluminum producers, ensuring consistent chemical composition, uniform grain structure, and reliable mechanical properties. Standard panel thicknesses include 1.5mm, 2.0mm, 2.5mm, and 3.0mm, with full customization available to meet project-specific structural, flatness, and durability requirements.

Material Specifications

Alloy Series: 3003 / 5005 / 5052 and other Aluminum Alloys

Thickness Range: 0.2 mm – 100 mm

Standard Width: 80 mm – 2650 mm

Standard Length: 500 mm – 16000 mm

Manufacturing Tolerance: Tight thickness and flatness control for architectural use

Surface Finishing Options

·PVDF (Fluorocarbon) Coating

·Powder Coating

·Anodized Finish

·Wood Grain & Stone Grain Thermal Transfer

·Special Decorative Finishes

- Color, gloss level, texture, and finish performance can be fully customized based on architectural design requirements.

Precision Manufacturing

·CNC cutting and precision shearing

·CNC punching, perforation, and routing

·Bending and forming (returns, flanges, stiffeners)

·Welding or riveting for structural reinforcement

·Surface coating and curing

·Final inspection, protection, and packaging

Advanced CNC machinery combined with flexible production lines allows for complex geometries, curved panels, perforated designs, and custom architectural shapes with excellent repeatability.

Custom Fabrication

We provides full project-based customization, including:

·Non-standard sizes and custom-shaped panels

·Special colors and architectural finishes

·Custom perforation patterns and open-area ratios

·Subframe, support system, and installation design assistance

Packaging & Logistics

Panels are packaged using professional export-grade protection methods:

- Individual protective film on each panel

- Foam padding and moisture-resistant wrapping

- Custom wooden crates or steel racks

- Clear labeling with size, part number, and installation orientation

Let us know if sample/Solution/Quote required.

Mail: [email protected]